DTF vs. Screen Printing: Key Takeaways

- Direct-to-Film (DTF) printing excels for small orders and one-offs, proving highly efficient for 1 to 24 pieces due to minimal setup. It handles complex, multi-color, and photorealistic designs with ease. DTF also offers broad material versatility, performing well on challenging fabrics like nylon and leather, and requires a lower initial investment with faster turnarounds.

- Screen printing, conversely, is the optimal choice for large volume orders (25+ pieces) of the same design, where its efficiency leads to significant per-unit cost savings. Ideal for simpler designs with fewer colors, it amortizes setup costs effectively over large runs. Screen printing is recognized for superior durability, vibrant opacity, especially on dark garments, and its unique ability to create specialty effects like metallic or puff prints.

Ultimately, the decision hinges on: Your typical order quantity, design complexity, desired print characteristics (durability vs. detail), initial budget, and target market.

Introduction

The custom apparel industry continues to evolve with advancing technology, offering print shop owners more options than ever before. Among these choices, Direct-to-Film (DTF) printing has emerged as a compelling alternative to traditional screen printing, prompting many business owners to reconsider their production methods.

This comprehensive guide compares DTF printing and screen printing across all critical factors—from initial investment and operating costs to print quality and production capabilities. Whether you’re starting a new printing business or considering adding capabilities to an existing operation, this detailed analysis will help you make an informed decision that aligns with your business goals, customer needs, and growth strategy.

Marcus Johnson

“The question isn’t whether DTF is better than screen printing or vice versa—it’s about understanding which technology best serves your specific business model and customer base. Many successful shops now strategically employ both methods to maximize their capabilities.”

Understanding the Technologies

To truly appreciate the strengths and differences of DTF and screen printing, it’s essential to grasp the fundamental mechanics of how each process works. While both methods result in decorated apparel, their underlying steps, equipment, and material interactions are distinct. Let’s delve into the basics of each.

Direct-to-Film (DTF) Printing: The Basics

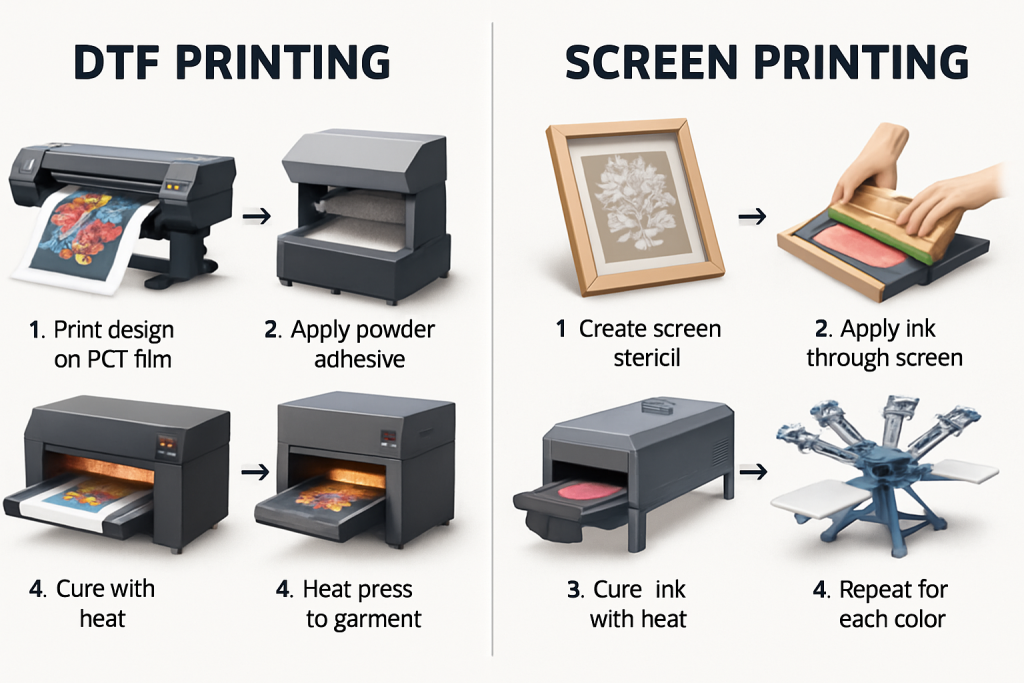

DTF printing is a relatively new digital printing process that involves:

- Printing directly onto a special PET film using digital printers with specialized DTF inks

- Applying a powdered adhesive to the printed design

- Curing the adhesive with heat to create a transfer

- Heat pressing the transfer onto the garment or substrate

The result is a durable, flexible print with excellent wash fastness and the ability to adhere to a wide range of materials.

Screen Printing: The Basics

Screen printing, a technique with centuries of history, involves:

- Creating screens (stencils) for each color in the design

- Placing the screen on the garment or printing surface

- Applying ink through the screen using a squeegee

- Curing the ink with a conveyor dryer or flash cure unit

- Repeating for each color in the design

The result is a vibrant, durable print with excellent opacity and color vibrancy.

Fun Fact: While screen printing dates back to ancient China during the Song Dynasty (960–1279 AD), DTF technology was only commercially introduced around 2019! Despite being relatively new, DTF has rapidly gained adoption due to its ability to combine digital printing convenience with screen printing-like durability.

Initial Investment Comparison

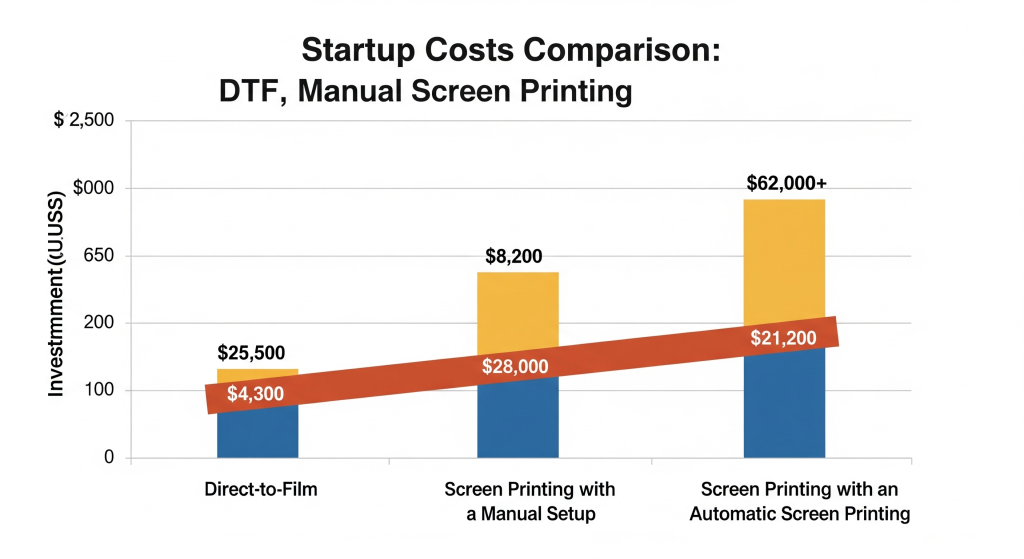

DTF Startup Costs

Starting a DTF printing operation requires:

Essential Equipment

- DTF printer: $2,000-$15,000 (entry-level to professional)

- Shaker/powder application system: $500-$3,000

- Heat press: $300-$2,500

- Curing oven (optional but recommended): $500-$2,000

- Computer and design software: $1,000-$3,000

Total Equipment Investment Range: $4,300-$25,500

Additional Startup Costs

Space Requirements

- Minimum workspace: 100-150 square feet

- Ventilation: Standard room ventilation usually sufficient

- Electrical: Standard 110V outlets (multiple circuits recommended)

Screen Printing Startup Costs

Starting a screen printing operation requires:

Essential Equipment

- Manual press (4-6 colors): $2,000-$6,000

- Entry-level automatic press: $15,000-$40,000+

- Exposure unit: $500-$3,000

- Flash cure unit: $1,000-$3,000

- Conveyor dryer: $3,000-$10,000

- Washout booth: $500-$2,000

- Screen rack: $200-$1,000

- Computer and design software: $1,000-$3,000

Total Equipment Investment Range:

- Manual setup: $8,200-$28,000

- Automatic setup: $21,200-$62,000+

Additional Startup Costs

- Initial supplies (screens, emulsion, ink): $1,000-$3,000

- Training and education: $500-$2,000

- Workspace modifications: Often substantial

Space Requirements

- Minimum workspace: 500-1,000+ square feet

- Ventilation: Specialized ventilation often required

- Electrical: 220V service often needed for larger equipment

DTF Startup Costs

Screen Printing Startup Costs

- Initial supplies (film, ink, powder): $500-$1,500

- Training and education: $0-$1,000 (many suppliers include training)

- Workspace modifications: Minimal (standard electrical, table space)

Key Investment Considerations

When evaluating initial investment, consider these factors:

Scalability

- DTF: Add additional printers as volume increases

- Screen Printing: Upgrade from manual to automatic press, add colors

Financing Options

- Equipment leasing typically available for both technologies

- DTF often has lower monthly payments due to lower initial cost

- ROI timeline differs significantly (covered in later section)

Hidden Costs

- Screen printing often requires more significant facility modifications

- DTF may require climate control for optimal performance

- Both technologies require ongoing maintenance

Sophia Rodriguez

“The initial investment gap between DTF and screen printing has made digital decoration accessible to many entrepreneurs who couldn’t afford the screen printing entry point. We’re seeing a new generation of print shop owners starting with DTF and growing into hybrid operations.”

Operating Costs and Profitability

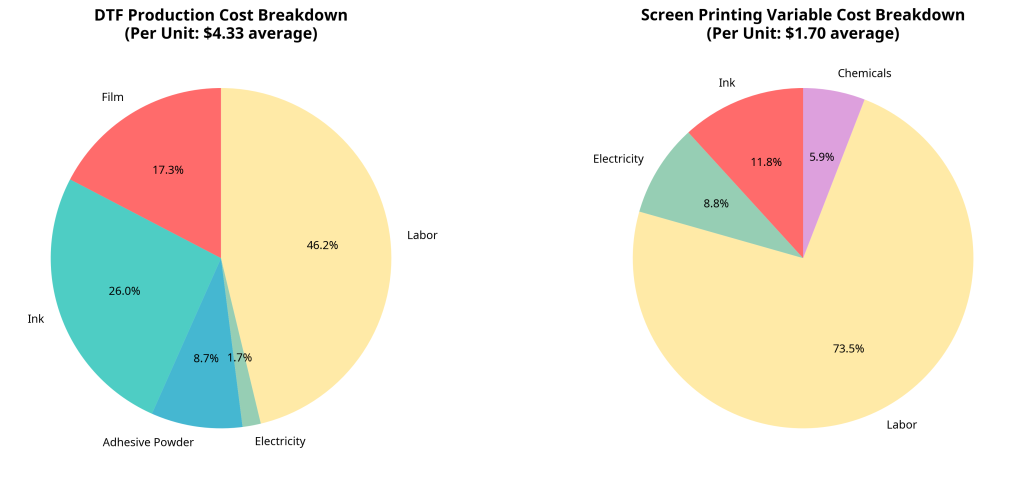

DTF Production Costs

The per-print cost structure for DTF includes:

Variable Costs Per Print (8.5" × 11" full-color design)

- Film: $0.50-$1.00

- Ink: $0.75-$1.50

- Adhesive powder: $0.25-$0.50

- Electricity: $0.05-$0.10

- Labor: $1.00-$3.00 (15-20 minutes total production time)

Total Variable Cost Range:$2.55-$6.10 per print

Fixed Costs

- Equipment depreciation

- Software subscriptions

- Workspace overhead

- Maintenance (minimal)

Production Speed

- Average output: 5-15 transfers per hour per printer

- Setup time between jobs: Minimal (5 minutes or less)

Screen Printing Production Costs

The per-print cost structure for screen printing includes:

Variable Costs Per Print (8.5" × 11" full-color design)

- Ink: $0.10-$0.30 (decreases with volume)

- Electricity: $0.10-$0.20

- Labor: $0.50-$2.00 (depends on automation level)

- Screen reclaiming chemicals: $0.05-$0.15

Total Variable Cost Range:$0.75-$2.65 per print

Fixed Costs

- Equipment depreciation

- Screen creation and storage

- Workspace overhead

- Maintenance (moderate)

Setup Costs (per design)

- Screen creation: $5-$15 per color

- Setup time: $20-$50 labor (30-60 minutes)

- Design separation: $10-$30

Production Speed

- Manual press: 40-60 prints per hour

- Automatic press: 300-500+ prints per hour

- Setup time between jobs: Significant (30-90 minutes)

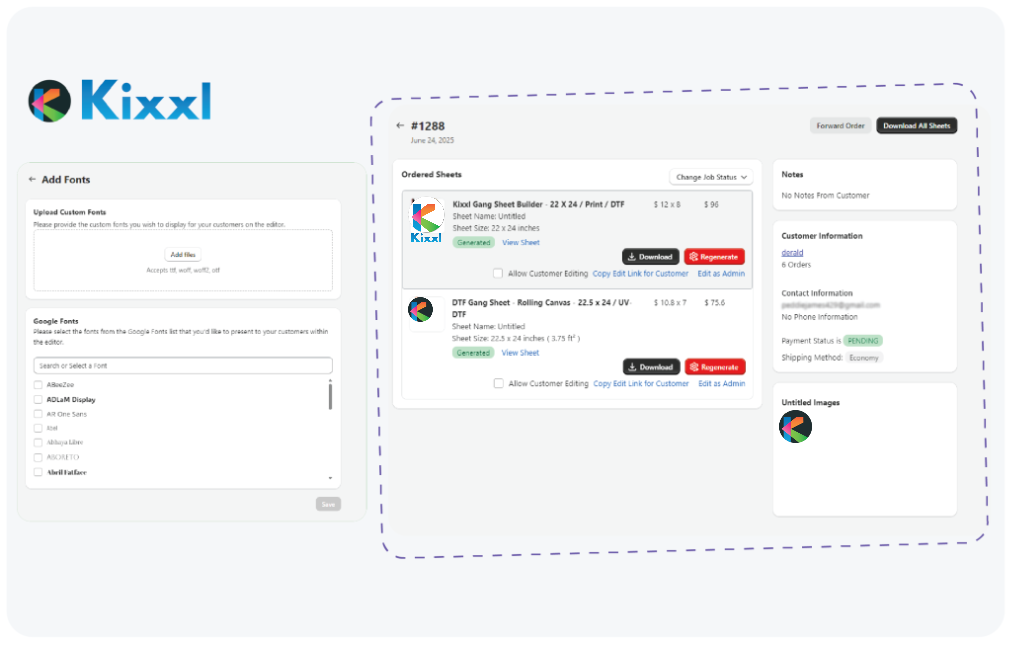

Did you know? Shops using Kixxl Gang Sheet Builder have reported 25%-30% decrease in their labor costs.

Break-Even Analysis

The economics of each technology vary significantly by order size:

DTF is typically more cost-effective for

- Orders of 1-24 pieces

- Multiple designs in small quantities

- Rush orders requiring quick turnaround

- Highly detailed, multi-color designs

- Print-on-demand business models

Screen printing is typically more cost-effective for

- Orders of 25+ pieces (same design)

- Simple designs with few colors

- Recurring orders of the same design

- High-volume production runs

- Specialty inks and effects

Break-Even Point Examples

- Basic 1-color design: ~15-20 pieces

- Full-color complex design: ~30-40 pieces

- Specialty prints (metallic, neon): Varies widely

The average print shop receives orders with quantities that follow a “power law” distribution—approximately 60% of orders are for less than 24 pieces, while only 10% are for more than 100 pieces. This distribution has driven the rapid adoption of DTF technology as a complement to traditional screen printing screen printing-like durability.

Print Quality and Capabilities

DTF Print Characteristics

DTF printing offers these quality attributes:

Visual Characteristics

- Resolution: High (600-1200 DPI)

- Color gamut: Wide (millions of colors)

- Gradients: Smooth, photorealistic

- Fine details: Excellent reproduction

- Opacity: Good to excellent with white underbase

- Edge definition: Very good

Physical Characteristics

- Hand feel: Lightweight, minimal texture

- Durability: Good (30-50+ washes with proper application)

- Stretch: Moderate to good

- Thickness: Thin to moderate

- Crack resistance: Good

Special Capabilities

- Photorealistic printing

- No color limitations

- Consistent results between prints

- No minimum order requirements

- Quick production of one-offs

Limitations

- Limited specialty effects (no puff, high-density, etc.)

- Maximum print size typically 13″×19″ (multiple transfers can be combined)

- Slightly less durability than screen printing for heavy-wear items

Screen Printing Characteristics

Screen printing offers these quality attributes:

Visual Characteristics

- Resolution: Moderate (45-65 LPI typically)

- Color gamut: Limited by number of screens

- Gradients: Challenging, often simulated with halftones

- Fine details: Limited by mesh count

- Opacity: Excellent, especially on dark garments

- Edge definition: Very good with proper technique

Physical Characteristics

- Hand feel: Varies from lightweight to heavy

- Durability: Excellent (50+ washes)

- Stretch: Depends on ink formulation

- Thickness: Controllable (thin to heavy)

- Crack resistance: Varies by ink type

Special Capabilities

- Specialty inks (metallic, glitter, puff, suede, etc.)

- High-density and textured prints

- Pantone color matching

- Extremely durable prints for workwear

- Very large format printing possible

Limitations

- Color limitations based on press capacity

- Challenging reproduction of photorealistic images

- Significant setup time and cost

- Minimum order quantities for profitability

Substrate Compatibility

Each technology offers different material compatibility:

DTF Works Well On

- Cotton, polyester, cotton/poly blends

- Nylon and water-resistant fabrics

- Leather and pleather

- Silk and delicate fabrics

- Wood, glass, metal (with proper powder)

- Dark and light colored materials equally

Screen Printing Works Well On

- Cotton, polyester, cotton/poly blends

- Canvas and heavy fabrics

- Paper and cardboard

- Specialized substrates with appropriate inks

- Better on light colors (dark requires underbase)

Challenging Applications

- DTF: Very stretchy materials without proper application

- Screen Printing: Highly textured surfaces, heat-sensitive materials

David Chen

“The substrate versatility of DTF has opened new markets for many print shops. Being able to print on nylon jackets, leather accessories, and even wood items without investing in specialized equipment has allowed businesses to say ‘yes’ to jobs they previously had to turn away.”

Workflow and Production Considerations

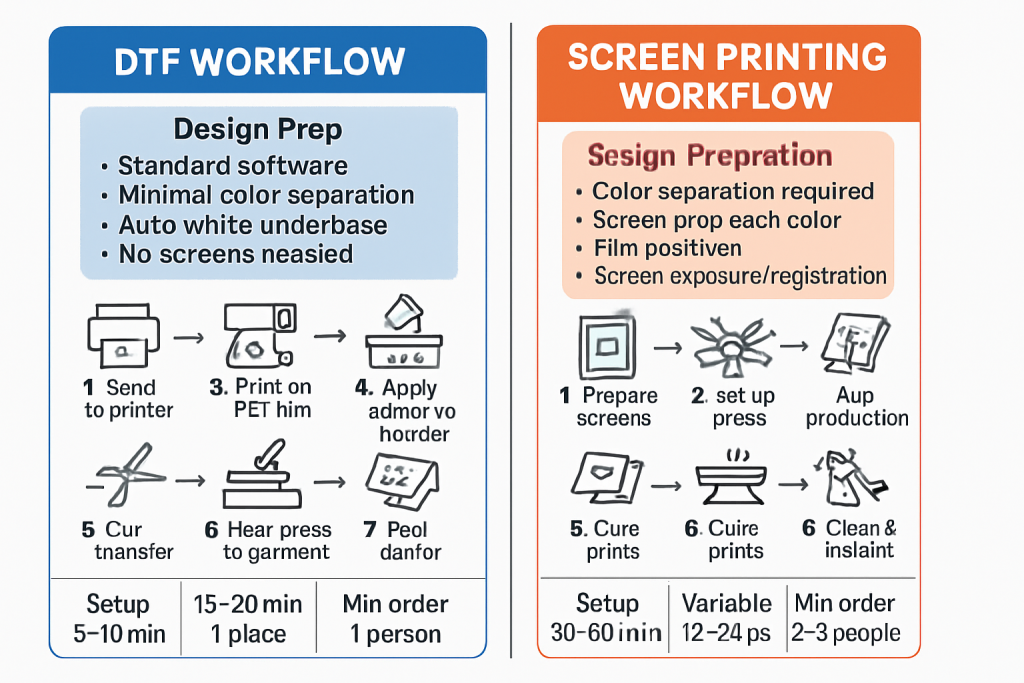

DTF Workflow

The typical DTF production process includes:

Design Preparation

- Standard design software (Photoshop, Illustrator, CorelDRAW)

- Minimal color separation required

- White underbase generated automatically by RIP software

- No screen preparation or film positives needed

Production Process

- Send design to DTF printer

- Print design on PET film

- Apply adhesive powder while ink is wet

- Cure adhesive with heat

- Cut transfer if needed

- Heat press transfer onto garment

- Peel carrier film

Turnaround Capabilities

- Setup time: 5-10 minutes

- Production time: 15-20 minutes for first piece

- Rush order capability: Excellent (same-day possible)

- Minimum viable order: Single piece

Staffing Requirements

- Entry-level: 1 operator can manage entire process

- Scaling: Linear (add printers and operators as needed)

- Skill level: Moderate technical skills required

- Training time: 1-2 days for basic proficiency

Screen Printing Workflow

The typical screen printing process includes:

Design Preparation

- Color separation required

- Screen preparation for each color

- Film positives needed

- Screen exposure, development, and registration

Production Process

- Prepare screens for each color

- Set up press with proper registration

- Print test prints and adjust as needed

- Run production

- Cure prints

- Break down press and reclaim screens

Turnaround Capabilities

- Setup time: 30-90+ minutes

- Production time: Highly variable based on quantity

- Rush order capability: Limited by setup time

- Minimum viable order: Typically 12-24 pieces

Staffing Requirements

- Entry-level: 2-3 staff (screen prep, printing, curing)

- Scaling: Step-function (manual to automatic press)

- Skill level: Significant technical skills required

- Training time: Weeks to months for proficiency

Production Planning Considerations

Key operational factors to consider:

Job Scheduling

- DTF: Flexible, can easily interrupt for rush jobs

- Screen Printing: Less flexible, setup time makes job changes costly

Production Space

- DTF: Compact footprint, clean operation

- Screen Printing: Requires significant space, wet/dry areas

Environmental Factors

- DTF: Temperature and humidity control important

- Screen Printing: Ventilation and chemical handling critical

Maintenance Requirements

- DTF: Daily maintenance routines, print head cleaning

- Screen Printing: Screen reclaiming, press maintenance

The average screen printing job requires 45-60 minutes of setup time regardless of the quantity being produced. For a 12-piece order, this means 4-5 minutes of setup time per garment! DTF virtually eliminates this setup overhead, making small orders economically viable

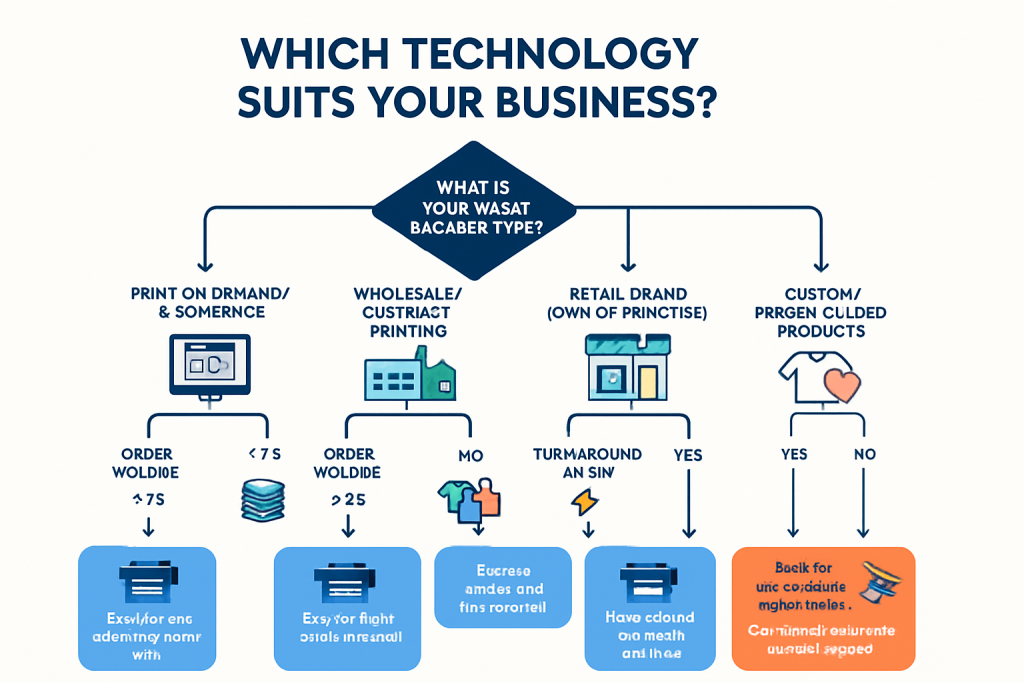

Business Model Compatibility

Ideal Business Scenarios for DTF

DTF printing aligns well with these business models:

Custom One-Offs and Small Runs

- Print-on-demand services

- Personalized gift items

- Sample production

- Prototype development

- Small business/team orders

Diverse Product Offerings

- Mixed-media printing (t-shirts, hats, bags, etc.)

- Specialty items (leather patches, wood items)

- Heat-sensitive materials

- Nylon and water-resistant products

Service Models

- E-commerce integration

- Quick-turn retail storefronts

- Mobile printing operations

- Home-based businesses

- Supplement to other decoration methods

Market Segments

- Direct-to-consumer

- Etsy and online marketplace sellers

- Local small businesses

- Event merchandise

- Family reunions and small gatherings

Ideal Business Scenarios for Screen Printing

Screen printing aligns well with these business models:

*Volume Production

- Contract printing for brands

- School and team sports

- Corporate apparel programs

- Event merchandise (large events)

- Retail brands with consistent designs

Specialty Printing

- Fashion-forward retail brands

- Specialty ink applications

- Textile design

- Industrial applications

- Athletic performance wear

Service Models

- Contract decorator for other businesses

- Wholesale printing services

- Licensed merchandise production

- Retail brands with standardized designs

- Fulfillment services for large orders

Market Segments

- B2B services

- Promotional product companies

- Athletic organizations

- Retail brands

- Large events and conferences

Hybrid Business Models

Many successful businesses leverage both technologies:

Strategic Implementation

- Use DTF for orders under 24 pieces

- Use screen printing for larger runs

- Leverage DTF for complex, multi-color designs

- Use screen printing for specialty inks and effects

- Employ DTF for rush orders and samples

Business Benefits

- Expanded service offerings

- Improved customer retention

- More competitive pricing at all quantity levels

- Reduced turn-away business

- Better equipment utilization

Implementation Approaches

- Start with DTF, add screen printing as volume grows

- Add DTF to existing screen print operation for small runs

- Outsource complementary technology until volume justifies investment

- Partner with complementary business for referrals

Jennifer Williams

“The most profitable print shops we work with have embraced a hybrid model. They’ve stopped seeing DTF and screen printing as competitors and instead view them as complementary tools in their production arsenal. This approach has allowed them to say ‘yes’ to virtually any order that comes through the door.”

(And with tools like Kixxl’s Order Forward Pro, your business can achieve this hybrid model flexibility even without owning all the equipment, by seamlessly partnering with other shops for specialized DTF or screen printing capabilities.)

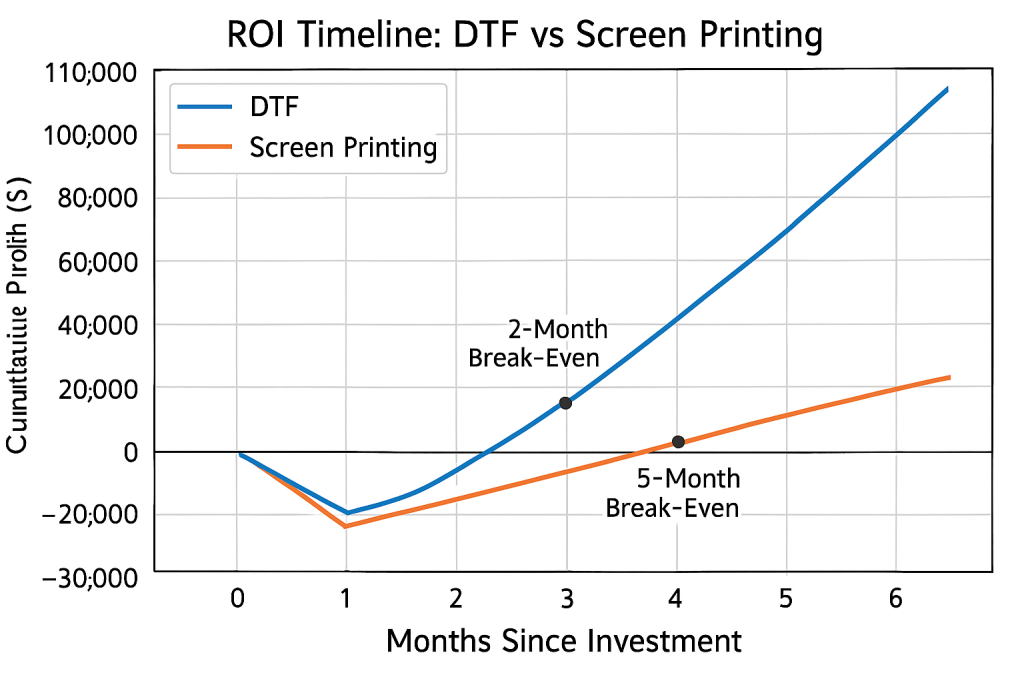

Return on Investment Analysis

DTF ROI Timeline

Financial projections for DTF investment:

Investment Scenario

- Equipment cost: $10,000 (mid-range setup)

- Monthly overhead: $500 (space, utilities, etc.)

- Average order: 6 pieces at $15 profit per piece

- Daily capacity: 8-10 orders

Typical ROI Timeline

- Monthly profit potential: $6,000-$9,000

- Equipment payback period: 2-3 months

- First-year ROI: 200-300%

Key ROI Accelerators

- No minimum order requirements

- Quick turnaround premium pricing

- Low setup costs

- Ability to run diverse products

Risk Factors

- Equipment reliability

- Market saturation in some areas

- Ink and supply costs fluctuations

- Learning curve for optimal production

Screen Printing ROI Timeline

Financial projections for screen printing investment:

Investment Scenario

- Equipment cost: $25,000 (basic automatic setup)

- Monthly overhead: $1,500 (space, utilities, etc.)

- Average order: 100 pieces at $3 profit per piece

- Daily capacity: 5-6 orders

Typical ROI Timeline

- Monthly profit potential: $7,500-$9,000

- Equipment payback period: 5-6 months

- First-year ROI: 100-150%

Key ROI Accelerators

- Volume efficiency

- Repeat orders with existing screens

- Multiple impressions from single setup

- Specialty ink premium pricing

Risk Factors

- Minimum order requirements limiting customer base

- Higher labor costs

- Significant training investment

- More complex production issues

Long-Term Financial Considerations

Beyond initial ROI, consider these long-term factors:

Equipment Lifespan

- DTF printers: 3-5 years before major components need replacement

- Screen printing equipment: 10-20+ years with proper maintenance

Ongoing Capital Requirements

- DTF: Print head replacements, potential technology upgrades

- Screen Printing: Screen replacement, frame inventory expansion

Market Adaptability

- DTF: Highly adaptable to changing market demands

- Screen Printing: Less flexible, but extremely efficient for stable products

Business Valuation Impact

- DTF: Technology depreciates quickly but requires less capital

- Screen Printing: Equipment holds value longer, represents larger asset

Print shops that implement both technologies report an average revenue increase of 32% in the first year! The combination allows them to capture business they previously turned away while optimizing production costs across their entire order spectrum.

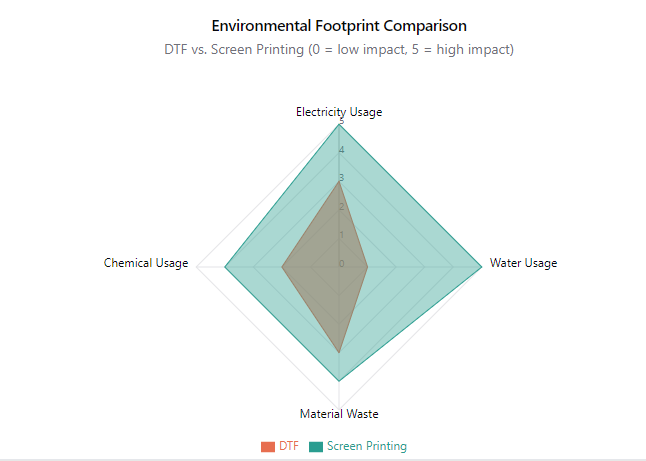

Environmental and Sustainability Considerations

DTF Environmental Impact

Environmental factors related to DTF production:

Resource Consumption

- Electricity usage: Moderate (printer, curing equipment)

- Water usage: Minimal to none

- Material waste: Film backing, excess powder

- Chemical usage: Ink waste, cleaning solutions

Sustainability Challenges

- PET film is not biodegradable

- Limited recycling options for film waste

- Ink cartridge/bag disposal

- Powder containment and disposal

Positive Environmental Aspects

- No water used in production process

- Minimal chemical exposure

- Lower energy consumption than screen printing

- Precise application reduces waste

- No screens or emulsion waste

Industry Improvements

- Biodegradable film development underway

- Water-based DTF ink options emerging

- Powder recycling systems becoming available

- Energy-efficient curing technologies

Screen Printing Environmental Impact

Environmental factors related to screen printing:

Resource Consumption

- Electricity usage: High (exposure units, dryers)

- Water usage: Significant (screen reclaiming)

- Material waste: Emulsion, ink, chemicals

- Chemical usage: Emulsion, degreaser, ink degradents

Sustainability Challenges

- Wastewater management

- Chemical storage and disposal

- High energy consumption for dryers

- Screen reclaiming chemical exposure

Positive Environmental Aspects

- Equipment longevity reduces manufacturing impact

- Water-based ink options widely available

- Efficient production for large runs reduces per-unit impact

- Established recycling programs for some materials

Industry Improvements

- Low-chemical reclaiming systems

- Energy-efficient dryer technology

- Water filtration and recycling systems

- Biodegradable emulsion options

Workplace Safety Considerations

Health and safety factors for each technology:

DTF Safety Considerations

- Ink exposure: Minimal with proper handling

- Chemical exposure: Limited to cleaning solutions

- Physical hazards: Heat press burns

- PPE requirements: Basic (gloves for cleaning)

- Ventilation needs: Standard room ventilation typically sufficient

Screen Printing Safety Considerations

- Ink exposure: Moderate with proper handling

- Chemical exposure: Significant during screen reclaiming

- Physical hazards: Press injuries, dryer burns

- PPE requirements: More extensive (respirators, chemical gloves)

- Ventilation needs: Specialized ventilation often required

Michael Torres

“The reduced chemical exposure and simplified waste management of DTF has been a significant factor for many businesses making the switch. Particularly for shops in areas with strict environmental regulations or those operating in residential or mixed-use buildings, DTF offers a path to growth with fewer regulatory hurdles.”

Future Trends and Technology Evolution

DTF Technology Trajectory

Where DTF technology is heading:

Near-Term Developments

- Faster print speeds

- Wider format options

- Improved white ink formulations

- More automated powder application systems

- Better RIP software with advanced features

Medium-Term Innovations

- Direct powder application (eliminating separate shaker)

- Biodegradable films

- Extended color gamut inks

- Integrated print-shake-cure systems

- Specialty effect capabilities

Long-Term Possibilities

- Roll-to-roll automated systems

- AI-driven color matching and quality control

- Dramatically reduced production times

- Expanded substrate compatibility

- Convergence with other digital technologies

Market Predictions

- Continued price reduction for entry-level systems

- Increased adoption by traditional screen printers

- Growing acceptance for retail and fashion applications

- Development of DTF-specific design techniques

Screen Printing Technology Trajectory

Where screen printing technology is heading:

Near-Term Developments

- More automated press features

- Improved registration systems

- Computer-to-screen innovations

- Enhanced ink formulations

- More environmentally friendly chemicals

Medium-Term Innovations

- Hybrid digital/screen systems

- Advanced curing technologies

- Automated quality control

- Reduced setup time innovations

- Improved specialty ink capabilities

Long-Term Possibilities

- Dramatically reduced environmental impact

- Highly automated workflow from design to production

- New specialty decoration capabilities

- Integration with other production methods

- Advanced materials compatibility

Market Predictions

- Continued dominance for high-volume production

- Increased specialization in effects digital can’t reproduce

- Growth in industrial applications

- Focus on sustainability and reduced environmental impact

Industry Convergence

How these technologies are likely to interact:

Hybrid Equipment Development

- Combined DTF/screen printing systems

- Shared curing technologies

- Integrated production workflows

- Complementary capabilities in single machines

Business Model Evolution

- Increased specialization by print method

- More outsourcing partnerships

- Technology-agnostic decoration services

- Production method determined by optimization algorithms

Market Impact

- Lower barriers to entry for new businesses

- More customization options for consumers

- Faster turnaround expectations

- Continued price pressure on basic printing services

Industry analysts predict that by 2027, over 70% of custom apparel print shops will operate hybrid production models incorporating both traditional and digital printing technologies! This convergence is creating entirely new business models that weren’t possible with either technology alone, especially with platforms like Kixxl’s Order Forward Pro enabling shops to seamlessly offer diverse services even without owning every piece of equipment.

Making the Right Choice for Your Business

Decision Framework

Follow this systematic approach to technology selection:

Step 1: Analyze Your Current Business

- Order quantity distribution

- Customer expectations

- Product diversity

- Turnaround requirements

- Available capital

- Space constraints

- Staff capabilities

Step 2: Evaluate Your Market Opportunity

- Local competition analysis

- Underserved market segments

- Growth potential areas

- Pricing sensitivity

- Quality expectations

- Turnaround demands

Step 3: Calculate Financial Projections

- Initial investment requirements

- Monthly operating costs

- Pricing strategy possibilities

- Volume requirements for profitability

- Cash flow implications

- ROI timeline

Step 4: Consider Implementation Factors

- Training requirements

- Space modifications needed

- Supplier support availability

- Maintenance capabilities

- Production workflow integration

Implementation Strategies

Approaches to adding new printing technology:

Phased Implementation

- Start with core technology that matches most orders

- Add complementary technology as volume justifies

- Develop expertise before expanding capabilities

- Scale equipment as demand grows

Hybrid From Start

- Invest in basic capabilities of both technologies

- Focus on workflow integration

- Develop versatile staff skills

- Market comprehensive capabilities

Specialization Strategy

- Focus exclusively on one technology

- Develop exceptional expertise

- Partner with complementary providers

- Build reputation in specific niches

Outsourcing Approach

- Invest in primary production method

- Establish outsourcing relationships for other methods

- Transition to in-house as volume justifies

- Maintain relationships for overflow capacity

Robert Martinez

“The most successful transitions I’ve seen involve careful planning and honest assessment of your business needs. Technology should serve your business model, not dictate it. Take the time to analyze your order patterns, customer expectations, and growth goals before making significant equipment investments.”

Conclusion: Beyond the Technology

The choice between DTF and screen printing—or implementing both—extends beyond equipment specifications and cost calculations. The most successful print shops align their technology choices with their broader business strategy, customer needs, and team capabilities.

Consider these final perspectives as you make your decision:

Business Identity Factors

- Are you positioning as a high-volume producer or custom specialist?

- Do your customers value price, quality, or turnaround most highly?

- Is sustainability a core value for your business and customers?

- Are you building for current demand or future growth?

Operational Realities

- What are your space limitations and expansion possibilities?

- What skills does your current team possess?

- How will technology choice affect your cash flow?

- What level of production complexity can you manage?

Market Positioning

- Which technology better serves your target customers?

- How will your choice differentiate you from competitors?

- Which technology better supports your pricing strategy?

- What capabilities do your customers request most often?

The printing industry continues to evolve, with both DTF and screen printing offering viable paths to success. By thoroughly understanding the strengths, limitations, and ideal applications of each technology, you can make an informed decision that positions your business for sustainable growth and profitability.

Frequently asked questions

If you have any unanswered questions, feel free to contact our support team via email. We’ll get back to you promptly to provide assistance.

- With proper application, DTF prints can achieve durability very close to screen printing, typically lasting 30-50+ washes. However, for extremely demanding applications like sports uniforms or workwear, screen printing still maintains a slight edge in long-term durability.

- Standard DTF doesn’t offer specialty effects like puff or high-density prints. However, some shops are experimenting with specialized powders and application techniques to achieve metallic and textured effects. Screen printing remains superior for specialty decorative effects.

- Screen printing typically has lower day-to-day maintenance costs but requires more significant periodic maintenance. DTF requires more consistent daily maintenance (print head cleaning, etc.) but fewer major service interventions. Overall maintenance costs tend to be similar when averaged over time.

- Many equipment suppliers and distributors offer sample printing services that allow you to see the same design produced with different technologies. This side-by-side comparison can be invaluable in making your decision.

DTF typically has a shorter learning curve (days to weeks for basic proficiency) compared to screen printing (weeks to months). However, mastering the nuances of either technology to achieve premium results requires significant experience and ongoing education.